Choosing the Right CO2 Laser Lens: Demystifying Diameter (Dia), Edge Thickness (ET), and Focal Length (FL)

So, you've just acquired your first CO2 laser machine, and you're eager to embark on your laser engraving and cutting journey. But before you dive in, it's essential to grasp the fundamentals of CO2 laser lenses—the critical components that can make a world of difference in your laser projects. Let's simplify the specifications you'll encounter when selecting CO2 laser lenses and explore why Diameter (Dia), Edge Thickness (ET), and Focal Length (FL) matter.

🔍 Diameter (Dia): The Basics

Diameter, often denoted as Dia, is one of the easiest lens specifications to understand. It simply refers to the size of the lens, typically measured in millimeters (mm). But why does size matter? In the context of CO2 laser lenses, the diameter determines the physical size of the lens. A larger diameter lens allows more laser energy to pass through, making it suitable for applications where power and throughput are crucial. Conversely, a smaller diameter lens offers precision and is ideal for detailed engraving and cutting tasks.

👉 Key Takeaway: Select a lens diameter that aligns with your project's power and precision requirements.

⚙️ Edge Thickness (ET): Going Beyond the Surface

Edge Thickness, or ET, refers to the thickness of the lens along its outer edge. This specification holds a special place in the world of laser engraving and cutting. Why? Because it influences how the laser beam interacts with the material you're working on. A lens with a thicker edge provides stability and robustness to the laser beam, making it ideal for tasks that require deep engraving and cutting through thicker materials. On the other hand, a lens with a thinner edge thickness is excellent for jobs that demand fine detail and precision.

👉 Key Takeaway: Consider edge thickness for stability in deep cutting or finesse in detailed engraving.

🔎 Focal Length (FL): Focusing on the Details

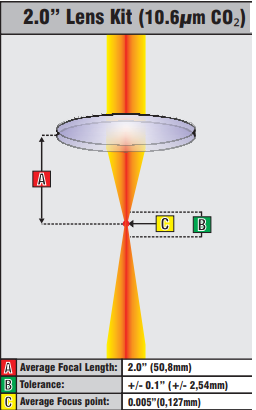

Focal Length, abbreviated as FL, is a critical specification that directly impacts the laser beam's focus and its interaction with the material. Typically expressed in millimeters (mm), focal length determines where the laser beam converges to a single point—the focal point. This point is pivotal because it dictates the distance from the lens to the focal point.

Short Focal Length (e.g., 1.5" or 2.0"): These lenses are like magnifying glasses, focusing the laser to a tiny, pinpoint spot. They excel in intricate and detailed engraving, where precision is paramount.

Applications: Perfect for intricate designs, small text, and high-resolution engraving. Ideal for materials like wood, acrylic, and leather.

Medium Focal Length (e.g., 2.5" or 3.0"): Striking a balance between depth and precision, these lenses are versatile and suitable for a wide range of engraving and cutting tasks.

Applications: Versatile for a wide range of engraving and cutting tasks. Suitable for materials like glass, rubber, and fabric.

Long Focal Length (e.g., 4.0" or 5.0"): When you need to engrave or cut thicker materials or require a more extended focal point, longer focal length lenses are the answer.

Applications: Ideal for deep engraving, cutting through thicker materials like cardboard, and specialty applications like cylindrical objects.

7.5" FL Lens: For maximum depth in your laser engraving and cutting projects.

Applications: Exceptional for achieving maximum depth in your engraving and cutting tasks.

Choosing the right lens depends on your project's requirements. Whether you're crafting intricate jewelry, creating signage, or customizing promotional items, understanding these specifications and their applications will help you achieve the desired results. Keep in mind that while these guidelines are helpful, experimentation and experience will also play a role in refining your laser engraving and cutting techniques.

Questions and Answers:

Q: What is the purpose of Diameter (Dia) in CO2 laser lenses?

A: Diameter, often denoted as Dia, is a critical specification in CO2 laser lenses. It refers to the physical size of the lens, typically measured in millimeters (mm). The diameter determines how much laser energy can pass through the lens. A larger diameter lens allows for more laser energy, making it suitable for applications where power and throughput are crucial. Conversely, a smaller diameter lens offers precision and is ideal for detailed engraving and cutting tasks.

Q: How do I measure the diameter of a CO2 laser lens?

A: Measuring the diameter of a CO2 laser lens is a straightforward process. You'll need a Vernier caliper or digital caliper for this. Here's how:

-

Open the caliper jaws.

-

Place the lens between the jaws.

-

Gently close the jaws around the lens.

-

Read the measurement displayed on the caliper in millimeters (mm).

This measurement will give you the lens's accurate diameter.

Q: How do I measure the Edge Thickness (ET) of a CO2 laser lens?

A: Measuring the Edge Thickness (ET) of a CO2 laser lens is a simple process that can be done using a Vernier caliper or digital caliper. Here are the steps:

-

Open the caliper jaws.

-

Place the lens horizontally, ensuring that its outer edge is in contact with one of the caliper jaws.

-

Gently close the caliper jaws around the lens, applying minimal pressure to avoid damaging the lens.

-

Read the measurement displayed on the caliper in millimeters (mm).

This measurement will provide you with the accurate Edge Thickness (ET) of the CO2 laser lens. It's essential to measure carefully to ensure precise results, as ET can impact the lens's performance in various laser applications.

Q: What is Edge Thickness (ET), and why is it important in CO2 laser lenses?

A: Edge Thickness, denoted as ET, refers to the thickness of the lens along its outer edge. This specification is crucial because it influences how the laser beam interacts with the material being worked on. A lens with a thicker edge provides stability and robustness to the laser beam, making it ideal for tasks that require deep engraving and cutting through thicker materials. On the other hand, a lens with a thinner edge thickness is excellent for jobs that demand fine detail and precision.

Q: Can you provide real-world examples of when Edge Thickness (ET) matters in laser engraving and cutting?

A: Certainly. Imagine you need to engrave a detailed pattern on a thin piece of wood. In this case, a lens with a thinner edge thickness is ideal, as it allows for precise engraving without damaging the delicate material. Conversely, if you're cutting through thick acrylic sheets, a lens with a thicker edge thickness provides the stability needed to maintain cutting precision.

Q: What is Focal Length (FL) in CO2 laser lenses, and how does it impact laser engraving and cutting?

A: Focal Length, abbreviated as FL, is a critical specification that directly affects the laser beam's focus and its interaction with the material. Typically expressed in millimeters (mm), focal length determines where the laser beam converges to a single point—the focal point. Short Focal Length lenses are ideal for intricate and detailed engraving, while longer focal length lenses are suitable for deep engraving and cutting through thicker materials.

Q: How do I measure the Focal Length (FL) of a CO2 laser lens?

A: Measuring the Focal Length (FL) of a CO2 laser lens is a straightforward process that requires a few simple steps. Here's how:

-

Prepare the Necessary Tools: You'll need a Vernier caliper or digital caliper, a stable surface, and the CO2 laser lens you want to measure.

-

Set Up the Lens: Place the CO2 laser lens on a flat and stable surface with the convex side facing up. Ensure that the lens is clean and free from any debris or contaminants.

-

Position the Caliper: Open the caliper jaws and position them so that one jaw rests gently on the flat surface, and the other jaw is suspended above the center of the lens.

-

Lower the Caliper Jaw: Slowly lower the suspended jaw until it makes light contact with the center of the convex side of the lens. Be careful not to apply too much pressure to avoid damaging the lens.

-

Read the Measurement: Carefully read the measurement displayed on the caliper in millimeters (mm). This measurement represents the Focal Length (FL) of the CO2 laser lens.

It's crucial to handle the lens with care and measure it accurately, as the Focal Length (FL) is a critical specification that affects the lens's performance in laser engraving and cutting applications.

Q: When should I use a 7.5" Focal Length (FL) lens, and what are its real-world applications?

A: A 7.5" Focal Length (FL) lens is ideal when you need to engrave or cut through thick materials or require an extended focal point. It excels in deep engraving, cutting through materials like cardboard, and specialty applications such as cylindrical objects. This longer focal length provides the depth and precision required for these tasks.

Q: Why is choosing the right CO2 laser lens essential for laser engraving and cutting projects?

A: Choosing the right CO2 laser lens is essential because it directly impacts the quality and precision of your laser engraving and cutting projects. The lens specifications, including Diameter (Dia), Edge Thickness (ET), and Focal Length (FL), determine how the laser beam interacts with materials. Selecting the appropriate lens ensures you achieve the desired results, whether you're working on intricate designs, detailed engraving, or cutting through thick materials.

Q: Where can I explore and purchase CO2 laser lenses with different specifications?

A: You can explore and purchase a variety of CO2 laser lenses with different specifications, including Diameter (Dia), Edge Thickness (ET), and Focal Length (FL), from reputable optics manufacturers and suppliers. Many of these manufacturers offer a range of lenses tailored to specific laser machine brands and models, ensuring compatibility with your equipment. Be sure to choose lenses that align with your project's requirements for the best results.

Q: Where can I find high-quality CO2 laser lenses with various specifications, including Diameter (Dia), Edge Thickness (ET), and Focal Length (FL), all in one place?

A: Look no further than American Photonics for your CO2 laser lens needs. With a specialization in high-power optics and a legacy of excellence dating back to 2001, American Photonics is your trusted source for precision lenses. We manufacture lenses that outperform the competition, providing you with the best results for your laser engraving and cutting projects.

Our lenses are crafted with the same ZnSe laser-grade raw material, ensuring consistent quality across all our products, whether for low-power or high-power applications. Made entirely in the USA and produced by a family-owned and operated manufacturing company, we take pride in delivering the finest lenses in the market.

Our commitment extends beyond manufacturing exceptional products. We're dedicated to assisting engravers worldwide and collaborating with laser machine manufacturers to enhance their product offerings. When you choose American Photonics, you're not only selecting the best lenses but also benefiting from our unmatched customer service.

Ready to explore our range of CO2 laser lenses with various specifications? Visit our product pages to find the perfect lens for your laser system:

- 12mm Diameter Lenses (2mm Edge Thickness)

- 12.7mm (1/2") Diameter Lenses (2mm Edge Thickness)

- 15mm Diameter Lenses (1.5mm Edge Thickness)

- 18mm Diameter Lenses (1.5mm Edge Thickness)

- 19mm Diameter Lenses (3/4" Diameter, 2mm Edge Thickness)

- 20mm Diameter Lenses (2mm Edge Thickness)

- 25.4 mm Diameter Lenses (2mm Edge Thickness)

- 25.4 mm Diameter Lenses (3mm Edge Thickness)

Elevate your laser work to new heights of precision and excellence with American Photonics CO2 laser lenses. Your journey to exceptional laser engraving and cutting starts here.

🔗 Explore Your Lens Options:

🎯 12mm Diameter Lenses (2mm Edge Thickness):

[1.5" FL Lens]: Precision Engraving

[2.0" FL Lens]: Versatile Detail

🎯 12.7mm (1/2") Diameter Lenses (2mm Edge Thickness):

[1.5" FL Lens](link): Precision Engraving

[2.0" FL Lens](link): Versatile Detail

🎯 15mm Diameter Lenses (1.5mm Edge Thickness):

[1.5" FL Lens](link): Precision Engraving

[2.0" FL Lens](link): Versatile Detail

[2.5" FL Lens](link): Balance of Depth & Precision

[4.0" FL Lens](link): Deep Engraving & Cutting

🎯 19mm Diameter Lenses (3/4" Diameter, 2mm Edge Thickness):

[1.5" FL Lens](link): Precision Engraving

[2.0" FL Lens](link): Versatile Detail

[2.5" FL Lens](link): Balance of Depth & Precision

[3.0" FL Lens](link): Versatile for Depth & Cutting

[4.0" FL Lens](link): Deep Engraving & Cutting

[5.0" FL Lens]( link): Maximum Depth

🎯 20mm Diameter Lenses (2mm Edge Thickness):

[1.5" FL Lens](link): Precision Engraving

[2.0" FL Lens](link): Versatile Detail

[2.5" FL Lens](link): Balance of Depth & Precision

[3.0" FL Lens](link): Versatile for Depth & Cutting

[4.0" FL Lens](link): Deep Engraving & Cutting

[5.0" FL Lens]( link): Maximum Depth

[7.5" FL Lens](link)

🎯 25.4 mm Diameter Lenses (2mm Edge Thickness):

[1.5" FL Lens](link): Precision Engraving

🎯 25.4 mm Diameter Lenses (3mm Edge Thickness):

[1.0" FL Lens](link): Precision Engraving

[1.5" FL Lens](link): Precision Engraving

[2.0" FL Lens](link): Versatile Detail

[2.5" FL Lens](link): Balance of Depth & Precision

[3.0" FL Lens](link): Versatile for Depth & Cutting

[4.0" FL Lens](link): Deep Engraving & Cutting

[5.0" FL Lens]( link): Maximum Depth

[7.5" FL Lens](link)

Get ready to turn your ideas into reality with the perfect CO2 laser lens. Your creative journey starts here! 🔥

#APC #CO2LaserLens #PrecisionEngraving #LaserEngraving #LaserCutting #LaserArtistry