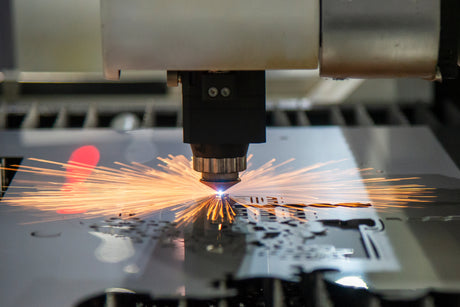

Top 5 Signs You Need to Replace Your CO₂ Laser Optics

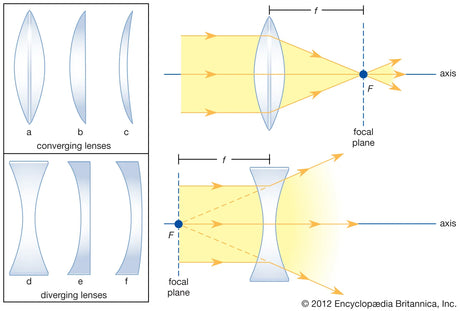

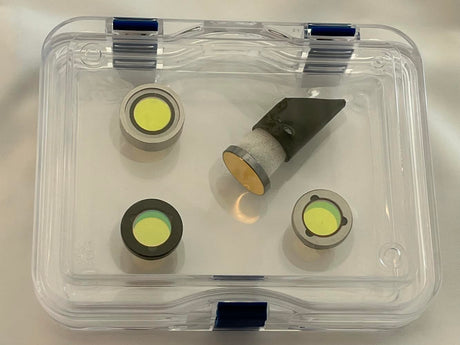

It’s crucial to ensure that your laser optics – such as lenses, mirrors, and beam splitters – are in optimal condition. Over time these components degrade, which can negatively impact...

Ana Walters |